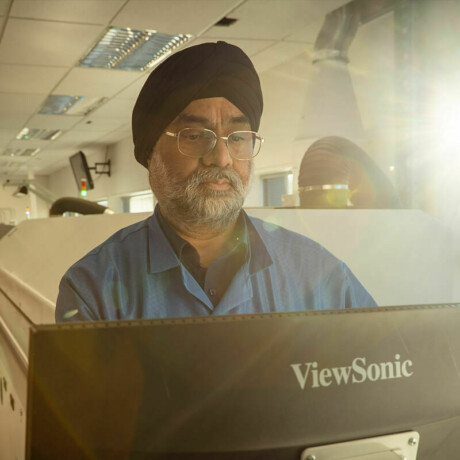

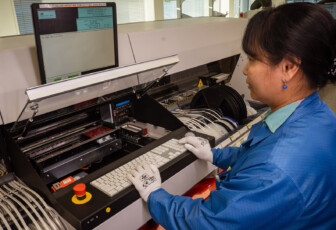

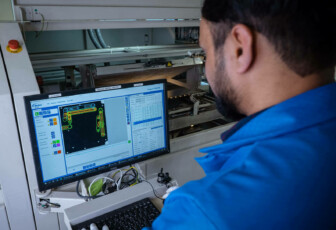

The equipment we use is carefully chosen to produce the most accurate results with the least waste possible. Several of our key pieces of equipment aren’t found anywhere else in New Zealand and allow us to provide high levels of flexibility and increased accuracy across each product we produce.

Class leading equipment and technology

Quality assurance and testing

We apply a high level of attention to detail to our processes, equipment, your products and the customer service experience to ensure quality and accuracy every step of the way. We work with you to manufacture and test products to your industry standards, and have the flexibility and many years of experience to create a process adapted for your needs. We also work with you through any specific testing regimes required for your product, to ensure maximum yields that provide a quality product at minimum cost.

How can we help your business stand out?

No matter what you’re creating, whether it’s complex and high-end or simple and cost-effective, your success relies on your product performing right. And we’re committed to making sure it does exactly that.